As we do conservation of artifacts from the Storm Wreck, we try to identify and work on pieces that are either unique or may have some identification or information pertaining to the ship. Some of the items that have gone through or are currently undergoing conservation include a 4-pound cannon, a 9-pound carronade, dozens of cannonballs, numerous cast iron cauldrons, pewter plates, spoons and thousands of nails.

As we do conservation of artifacts from the Storm Wreck, we try to identify and work on pieces that are either unique or may have some identification or information pertaining to the ship. Some of the items that have gone through or are currently undergoing conservation include a 4-pound cannon, a 9-pound carronade, dozens of cannonballs, numerous cast iron cauldrons, pewter plates, spoons and thousands of nails.

These artifacts were all chosen because they had the potential to have some diagnostic numbers or maker marks on them. They were also chosen because they were easily identifiable while excavating and X-raying. One common theme uniting all of these artifacts is that they are all big solid pieces or clumps of hundreds of little bits of metal.

Unfortunately, in maritime wrecks most of the surviving material is going to be metal. This makes conservation easier, since the same processes can be used for almost all the different metallic objects.

However, it is a nice break and a challenge when we come across organic materials.

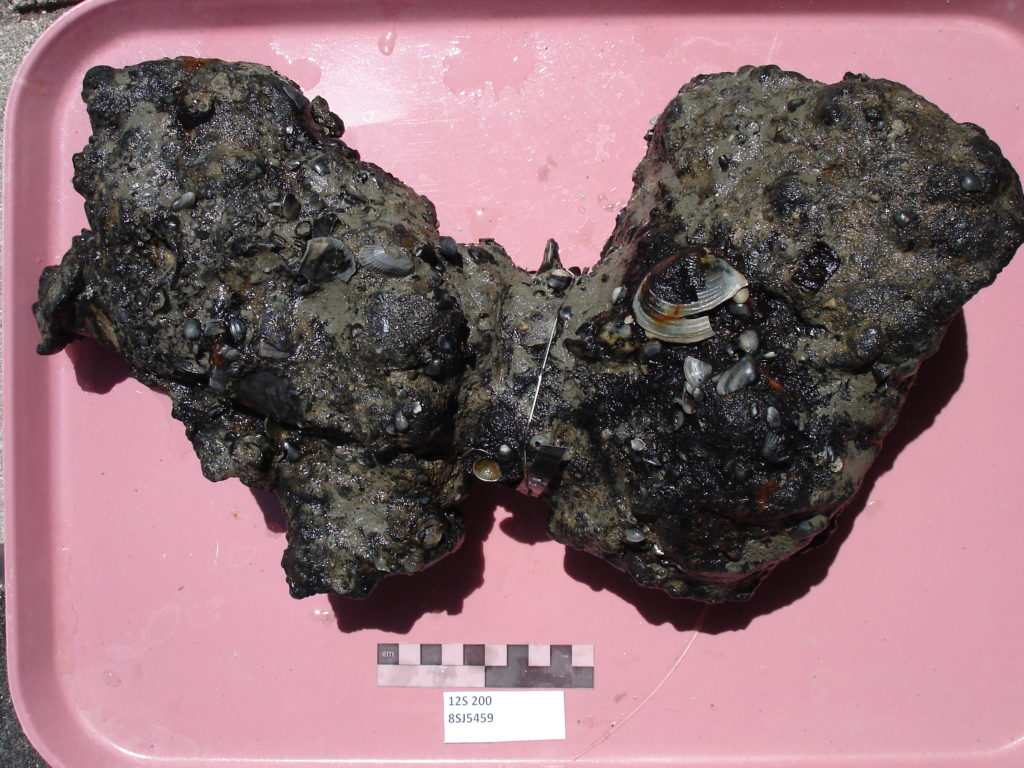

Artifact 12S 200 was excavated during the 2012 LAMP field school. At first, it did not look like much.

It appeared to be a standard concretion of shell and sediment over a few different objects. But, when X-rayed, the unremarkable blob turned out to be very interesting.

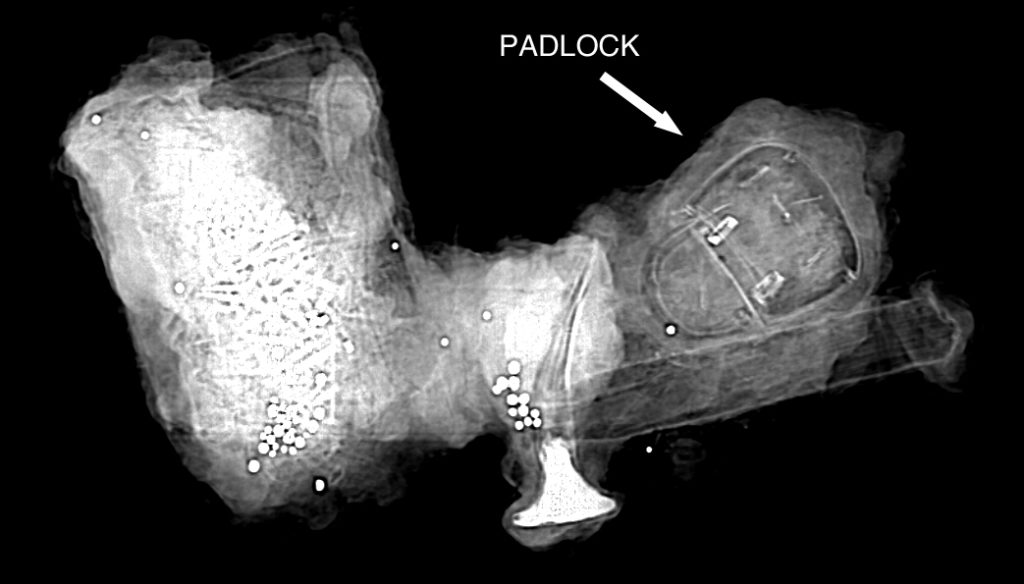

Two items immediately jumped off the screen. The easiest to recognize is the profile of a hammer on the bottom of the image.

Just above and to the right is an artifact that is a little harder to tell. What looks like a little, round handbag is actually a padlock.

At the top of the X-ray is a jumbled mess of iron nails and small lead birdshot.

So, why is this concretion so interesting? Personally, it is because of the hammer.

As mentioned above, most materials we see from shipwrecks are metal. The hammer in the x-ray, though, looked like it still had an intact wooden handle.

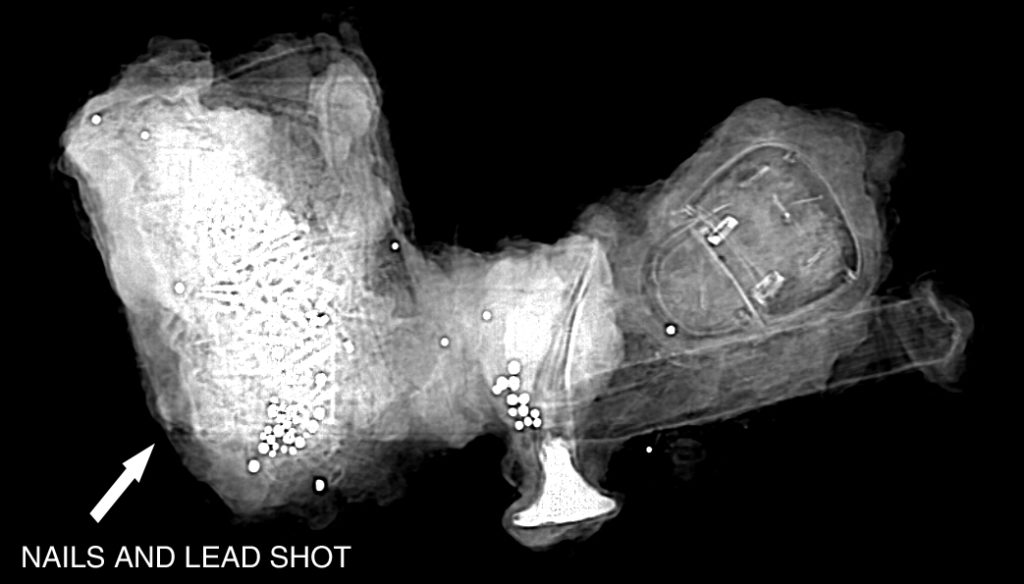

I began by air scribing the concretion just above the top of the hammerhead in order to separate the nails from the rest. Once the nails and lead shot were removed, they were set aside as future conservation training for volunteers.

Next, I carefully started air scribing between the hammer and the padlock. The two artifacts need to be conserved separately and both appeared to be very fragile. The metal of the padlock looked to be almost completely corroded away, leaving a hollow void inside the concretion. It was difficult to tell what the condition of the wooden handle was until actually exposing it.

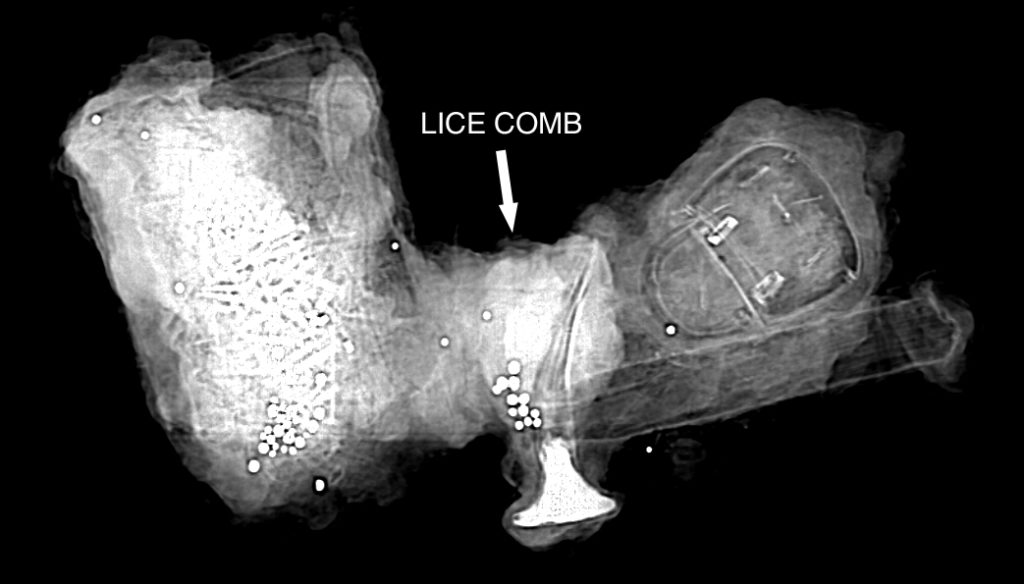

While air scribing the reverse side of the hammerhead, another intriguing artifact showed up. A small lice comb was hidden inside the sediment. It appears to be made of bone, ivory or wood, but is difficult to determine at this point. Because it is organic, it did not show up very well in the x-ray.

Unexpected lice comb.

The comb was removed and placed into purified water to stay wet and gradually remove the staining from the material.

Finally, after separating the lock and the comb, I started to air scribe the hammer. I was pleased to find that the wood was in excellent condition and had remained nearly intact. The iron head of the hammer, though, was not as fortunate and there were some voids of corroded metal. While the missing iron is not ideal, it is a blessing in disguise, as the corrosion most likely helped preserve the wood. As iron rusts and breaks down underwater, the iron corrosion product will bleed into and impregnate the wood as the sediment builds up around it. Sea life that eats organic material will leave the wood alone when this happens.

Nevertheless, I had to account for the missing metal. I cleaned out the hollow spots of any remaining iron and poured resin epoxy in to fill, strengthen and replicate the absent material.

When the epoxy cured and set, I was able to start cleaning the wood. I used dental picks and toothbrushes to carefully scratch off remaining sediment. When I had removed as much as possible, I placed the hammer into two chemical solutions. I first placed the hammer handle in a mixture of purified water and ammonium citrate. The ammonium citrate is a chelating agent and helps draw out the residual iron that has bled into the wood. Next, I put the wood in hydrogen peroxide for short durations to help remove some of the staining. I had to be careful with the hydrogen peroxide, as too much exposure would bleach the wood and turn it into an unnatural coloration.

I am currently still gradually cleaning the wood with the chemical baths before placing the hammer in its final conservation treatment.

Andrew Thomson is the Assistant Conservator for the St. Augustine Lighthouse & Museum. He received his graduate degree and training from the Conservation Research Laboratory at Texas A&M.