The most recent project at the LAMP Boatworks. Foreground left is the Chaisson dory tender, a 17′ spritsail skiff to right, and a 1760s ship’s yawl in the background.

A quick update, since I’ve been remiss in sending one for a while. I hope this finds you all in kindred spirits and enjoying this fine weather. Things around the boatworks have been heating up this spring and continue to simmer at a solid pace.

The sheer lines of Tarheel, a 17′ spritsail skiff being built at LAMP Boatworks.

The Chaisson is almost done and we have already sold almost $200 worth of raffle tickets for her. Next up is a Shellback dinghy. I ordered the plans this morning from WoodenBoat Store and she will begin construction here in the next few weeks. Speaking of construction, the chips have been flying around Tarheel and the Yawlboat, Dr. Jim and Maury (et al) have three strakes applied to her sides and if you stand in front of her bows and stare at her, it is beginning to look like a boat! Tarheel is coming along nicely and also beginning to show her lines. I worked on her oars this weekend after Jim was kind enough to let me borrow his shop on Saturday morning to make the 45’ +/- linear feet of cutting required to make two 9’ Pete Culler oars. Once the electronic whittling had been done, I returned to Salt Run Lodge (aka my pad) and spent the remainder of the weekend shaving away at them. They are about 90% done now and I’ll finish them sometime in the next couple of weeks. A nice coat of white paint, gray blade tips, and a maroon star on each blade should give them a nice traditional, albeit if not almost snooty, look. Jerry was a big help last week in scarfing together wood for a sprit, that long toothpick of a pole has now been reduced to a 17’ long octagon. So far the wood count for the boat includes: Florida cypress, Virginia white oak, Florida live oak, Florida yellow pine, Canuck spruce, God-knows-where sapele, and Northwest Doug fir. A mélange of woods, no doubt. Next up is her rudder post and then I can bolt her hind-end together in preparation for her bottom sheathing. Is it unnatural to want to skip vacation to work on the boat instead? Is it possible I hit myself on the head with one of the oars to cause this malady? Is it because I just got in a new Veritas sharpening system and have new life on all of my blades (you can’t just NOT cut something with a freshly honed blade!)?

Shellback Dinghy (photo courtesy of Monte Copeland)

Ralph Koebke is in the shop today for a tuneup on his heart. He is in Shands Hospital and will be there for a couple days. We all wish him a painless operation and a speedy recovery. Please keep Ralph and his wife in your thoughts. We need him back to continue firing shots over the bow of woebegone, devil-besot, malady-inflicting engineers who think they know what nails are thinking when embedded in wood. Think I hit my head again? Pick up the latest copy of WoodenBoat magazine and see Ralph’s most recent epistle, I am told it is a monument to calculated rejoinder. Ralph also is working on “Hydrostatic Properties of a 17’ Skiff”, an algorithmic interpretation of the theoretical buoyant characteristics of Tarheel. If you are interested in numerical integration, Simpson’s rule, and figuring out what the righting arm effect is from a full bottle of Pabst’s Blue Ribbon left 12’ from the centerline is I have a copy and will be happy to provide one to anybody who asks. Ralph provided a very nice introductory statement at the beginning to try and explain what the arithmetical calisthenics really mean and how they are devised. It makes doing your taxes a simple, fun and enjoyable experience! Many thanks Ralph, be well friend and return to us hale!

I will be departing for Seattle next week. The goal is to attend two training workshops being hosted by the Center for Wooden Boats (Seattle, WA) and Alexandria Seaport Foundation (Alexandria, VA). The goal for the two conferences is to figure out what sort of programming works with boatbuilding programs such as ours. Why, you ask, is this important and why us? As you all know we have a vibrant and vigorous program here that has grown and established itself over the past five years. We have built boats for exhibit, for a yearly drawing, and for the valuable sake of historic recreation and skill preservation. All of these are noble and worthy goals. However, it is worth investigating other opportunities for the program not to grow it for the sake of growth (the ideology of the cancer cell) but to involve a wider audience and possibly draw out the program into more days of the week. I have been here on the weekends a fair amount during the past month working on my project and multitudes of our guests wander over to the boatworks and want to see what is going on. Similarly, there might be programming opportunities with local groups ranging from the young to the seasoned that can endow us with more resources, provide more back to the community, and fulfill an even greater purpose. The first training session is called “Teaching with Small Boats” and discusses how programs have been developed that use the boats produced by boatworks around the country for educational things. We are a light station and if we can instill maritime skills in youth from our area, especially those who aren’t prone to getting out on the water, we enhance our mission. The second half is called “Building to Teach” and we will learn about designing curricula that teaches young people math and science skills while building boats and working with wood. This program has been a tried and true success for Alexandria Seaport Foundation for many years and they want to let other organizations know how to do best do it. I want to thank Maury Keiser for putting this idea in front of LAMP and helping to make it happen.

We have had some trouble with oar thievery, and I ordered a locking oar holder this morning. The oars should have been secured and LAMP will make sure this sort of thing is history. I will take the new security lock over to Capo’s welding shop to see if they will cut some more out for us out of aluminum to use on future boats.

So, a lot is going on. I will be out of the office for the remainder of the week on vacation (pickling myself on a South Florida island and doing nothing of import) but call me if you have any questions about anything I’ve written today. I will warn you though, you may be talking to an intoxicated person. Below is a link to the training workshops below for you to peruse. Have a great week and I’ll see you guys next Tuesday!

http://www.buildingtoteach.com/

http://teachingwithsmallboats.org/2012%20TWSB%20Conference%20Registration%20Form%202.0-jy-1-9-0825.pdf

Keep the wood flying,

-Brendan

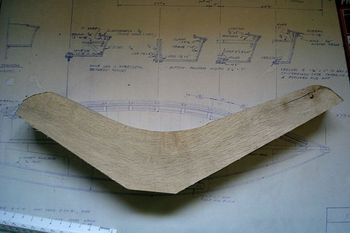

Transom knee for Tarheel out of live oak from one of Gamble Rogers’ trees. Ready for final sanding and installation!